Skived Fin Heat Sink

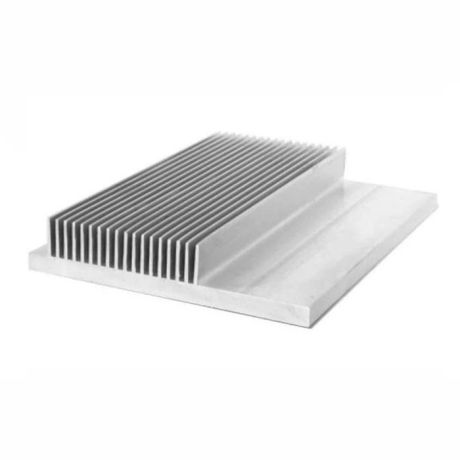

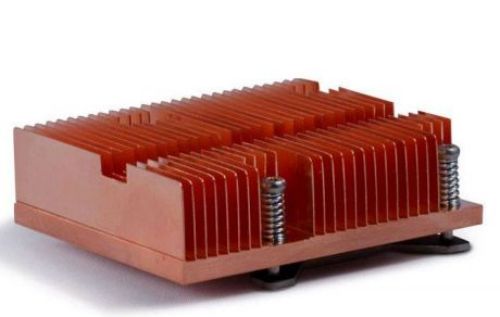

When the fin density cannot be achieved by extrusion technology, the skived fin heat sink can replace the extruded heat sink. Skived fin heat sink can be made of copper or aluminum, and usually have 0.5 (0.020 inch) thick heat sinks.

When the fin density cannot be achieved by extrusion technology, the skived fin heat sink can replace the extruded heat sink. Skived fin heat sink can be made of copper or aluminum, and usually have 0.5 (0.020 inch) thick heat sinks.

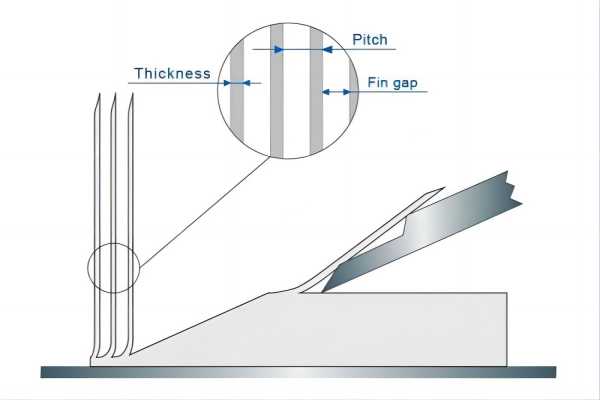

Skived fin heat sink: When passing the machine, scrape the board to a specific angle to form and bend the heat sink. Through repeated cutting, it forms a consistent gap and structure, which can be used to cool high-power equipment under air-cooled conditions. Compared with the stitched fin process, this process can increase the cooling capacity by 8-15%. Leading heat dissipation with innovative high density, high performance, high aspect ratio and excellent performance.

Parameter Of Skived Fin Heat Sink

Material | Specification | Application |

| Aluminum 6063 | 4 foot max profile width | Limited space |

| Pure Copper CDA 110 | <= 10 in profile length | Forced airflow |

| 40:1 fin height to minimum gap ratio | Servers | |

| <= 50 mm maximum fin height | Networking / Telecom boards | |

| 0.2 – 1.0 mm fin thickness |

Finned tube radiators are generally used for heating or cooling air, and have the characteristics of compact structure and large unit heat transfer area. Widely used in various fields such as textiles, printing and dyeing, petroleum, chemical industry, drying, power, etc. The most widely used finned heat sink is currently steel aluminum finned tube (wound steel aluminum composite finned tube, rolled steel aluminum composite finned tube), which utilizes the pressure resistance of steel pipes and the efficient thermal conductivity of aluminum, and is compounded on specialized machine tools. Its contact thermal resistance is almost zero under operating conditions of 210 ℃.

Use a sharp knife to produce a scraped heat sink. When the knife passes over the material, it curls a small thickness of metal and then bends it vertically to form a heat sink. The shaved fin is made of a piece of material, and then cut into a certain length according to the requirements of the final application.

Because the fins are thin, care must be taken to prevent damage during handling. It is recommended to place a shield above the heat sink to prevent damage.

Some application of Skived Heat Sink

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more