Cold Forging Heat Sink

Cold forging is the forming process of materials below the recrystallization temperature, which is carried out below the recovery temperature. Cold forged materials are mostly aluminum and some alloys with low deformation resistance and good plasticity at room temperature. Cold forging has good surface quality and high dimensional accuracy, which can replace some cutting processes. Cold forging can strengthen metals and improve the strength of parts.

Cold forging is the forming process of materials below the recrystallization temperature, which is carried out below the recovery temperature. Cold forged materials are mostly aluminum and some alloys with low deformation resistance and good plasticity at room temperature. Cold forging has good surface quality and high dimensional accuracy, which can replace some cutting processes. Cold forging can strengthen metals and improve the strength of parts.

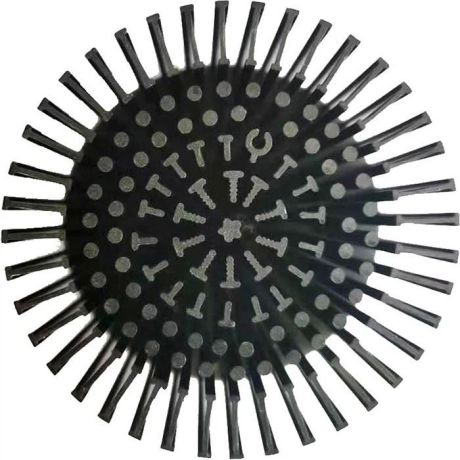

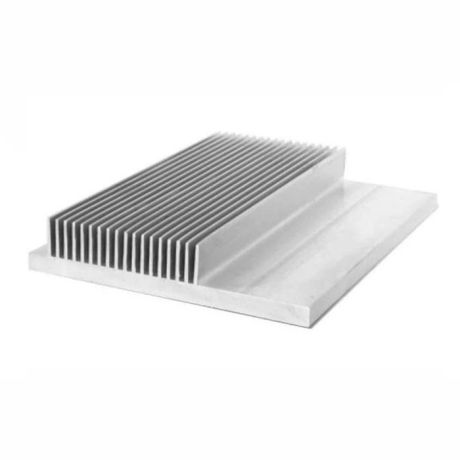

Cold forged integrated radiator is an efficient radiator manufactured through cold forging forming. The appearance of the radiator is a compact and integral structure, with multiple heat dissipation fins inside, which can quickly dissipate the heat generated by electronic devices.

Compared with traditional radiators, cold forged integrated radiators have higher heat dissipation efficiency and better stability. Firstly, due to the use of cold forging integrated forming technology, the spacing between the internal fins of the radiator is more uniform, thereby fully utilizing the heat dissipation area. At the same time, the design of the fin shape is also more reasonable, which can maximize the increase of heat dissipation area and improve heat dissipation efficiency.

In addition, the cold forged integrated radiator adopts high-quality copper material during the manufacturing process, which has better thermal conductivity. This allows for the rapid absorption and dissipation of heat generated by electronic devices, preventing performance degradation or damage caused by overheating.

In addition, the cold forged integrated radiator also has better stability. Due to its integrated structure, its assembly is very simple, unlike traditional radiators that require the use of screws and other spare parts for fixation. This not only makes the radiator more sturdy, but also avoids problems such as looseness, further improving stability.

In summary, the cold forged integrated heat sink is an efficient and stable heat sink with higher heat dissipation efficiency and better stability, especially suitable for use in some high-performance electronic devices. With the continuous development of electronic technology, the application of this heat sink will also become increasingly widespread.

Advantages of Cold Forging

The cold forged radiator has good thermal conductivity, good heat dissipation structure, large heat dissipation area, small size and light weight, and excellent appearance and texture (the material of the cold forged radiator is pure aluminum, and the surface can be anodized, which is smooth and bright. It can also be oxidized in different colors (silver, gold, black, etc.) according to customer needs.

Cold forged heat sinks are widely used for heat dissipation in LED lighting fixtures, with the following advantages:

(1) The price of cold forging molds is not high, which can effectively control costs;

(2) High production capacity, suitable for mass production;

(3) The mold production cycle is relatively short, usually 10 to 15 days;

(4) Once formed, the heat dissipation performance is consistent with the material heat dissipation performance, and the later processing steps are few and simple.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more