CNC Turning Service

CNC turning is a typical reduction manufacturing process that uses cutting tools to remove some material from the outside of the material. When the workpiece is rotating (continuously rotating), excess fragments are cut off until it reaches the desired shape, diameter, and size of the final product.

CNC turning machining is controlled by the numerical control system through servo drive systems to control the movement of various parts. It is mainly used for multi-process machining of axis and disc rotary parts, with comprehensive characteristics such as high precision, high efficiency, and high flexibility. It is suitable for small and medium batch production of complex-shaped parts with multiple varieties and specifications. Most workpieces with rotating surfaces can be machined using turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces.

CNC Turning Service Accuracy: ± 0.1 mm / 100 mm

Product Desriciption

| Item | CNC Turning Service |

| Materials | Aluminum alloy, copper (purplish red luster), stainless steel, titanium alloy, magnesium alloy, zinc alloy |

| Accuracy | ±0.1mm/100mm |

| Maximum Molding Size | 3000*1200*850mm |

| Surface Treatment | Deburring, polishing, polishing, sand blasting, oxidation, electroplating, black oxide, wire drawing, silk screen, laser engraving, spraying metal oil, powder spraying, chromate, spraying rubber oil, silk screen, heat treatment, passivation, etc. |

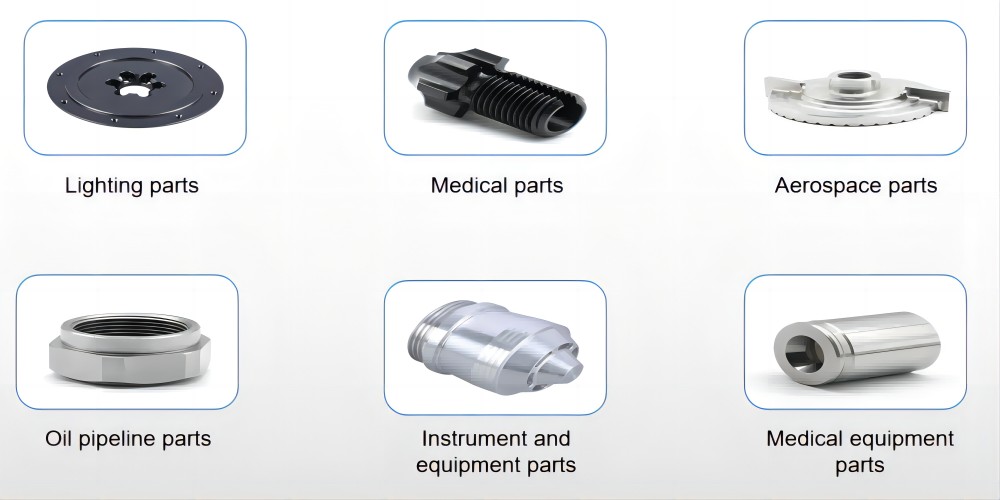

Application of CNC Turning Service

Advantages of Using CNC Turning Machining:

1、 CNC turning can process parts that require multiple processing steps after one clamping and positioning.

2、 High machining accuracy, stable and reliable machining quality.

3、 From the cutting principle of CNC turning, whether it is end milling or circumferential milling, it belongs to intermittent cutting mode, unlike continuous cutting like turning. Therefore, the requirements for cutting tools are high, with good impact resistance, toughness, and wear resistance. In dry cutting conditions, good red hardness is also required.

4、 CNC turning of parts has strong adaptability and good flexibility, and can process parts with particularly complex contour shapes or difficult to control dimensions, such as mold parts, shell parts, etc.

5、 Capable of CNC turning parts that cannot be machined by ordinary machine tools or are difficult to machine, such as complex curve parts described by mathematical models and three-dimensional curved surface parts.

6、 The production automation program is high, which can reduce the labor intensity of the operator. Beneficial for automated production management.

7、 High production efficiency

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more